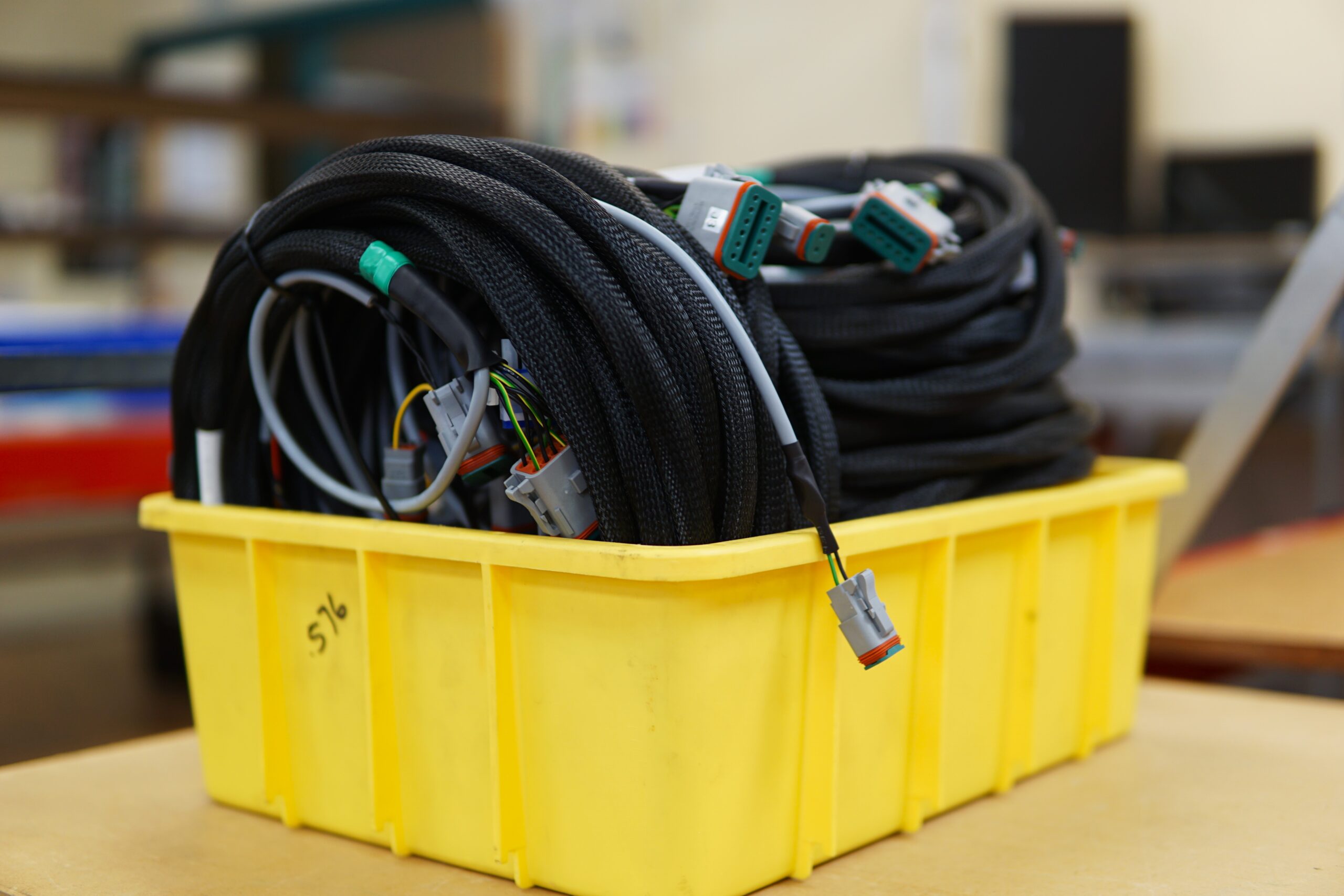

BJC rival the best in the world with state-of-the-art wiring assembly solutions and manufacturing capabilities. All of our wiring products are built to withstand the intense demands of the industry, and we have the ability to source and process a vast range of components, sub-assemblies, and wire types.

Information

Our capabilities include:

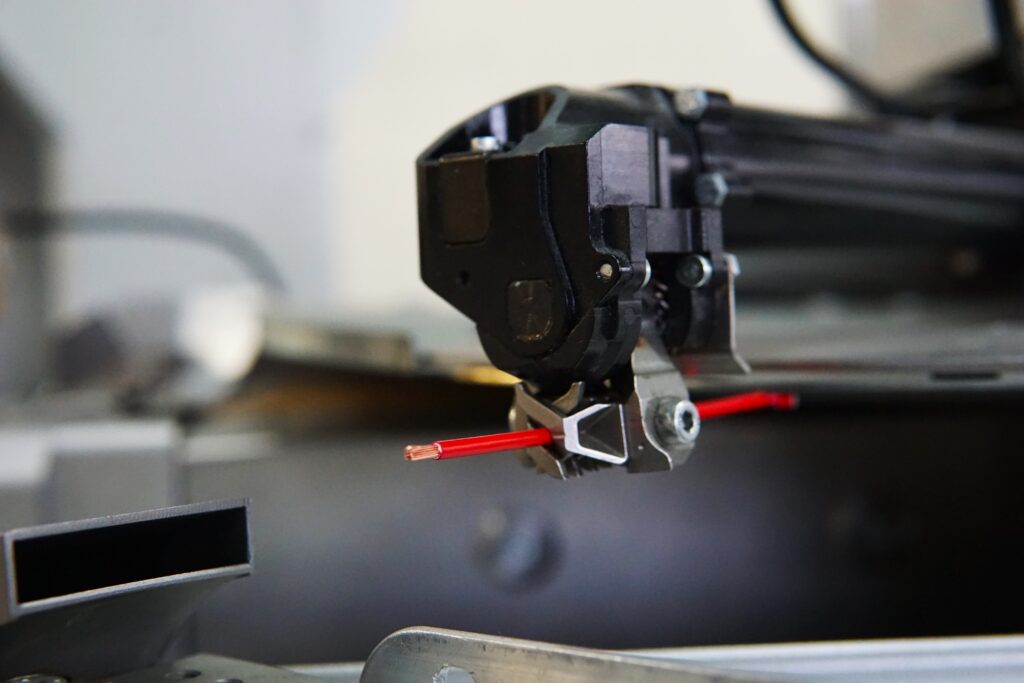

- Wire preparation of both single and multi-core cables, and automatic wire and terminal processing.

- Industry-specific custom wiring looms: automotive, agriculture, horticulture, medical, forestry, marine, and communications and more.

- Battery Cables, Adaptor cables, Cable kits

- Control Panels: Full contract assembly, labelled panel wiring kits

- Automotive control boxes

- Automotive add-on and trailer kits

- Boom Looms

- Full contract assembly

- Control unit wiring

- Custom wire printing and labelling

BJC can assist you in the assembly and manufacture of many types of cable assemblies, interface cables, wiring harnesses, control box and cabinet assembly. At its most basic, this could be a single core cable, cut to length and stripped for insertion into a PCB or terminal block, through to complete custom assemblies and wiring harnesses containing multiple cables and wires of different lengths, sleeves, crimp terminals and connectors. We have automated cut and strip equipment, automatic and manual crimp machines, as well as an extensive inventory of wire and components.

No matter how precise or vague your wiring requirements, we are always happy to discuss these with you. Our knowledgeable design team will consult with you on your harness design, component specification, and manufacturing technique requirements and can provide suggestions and alternative options where possible.

Our Wellington based manufacturing and warehousing facility has the capacity for quick turnaround, storage and onward despatch if required. To discuss or receive a quote for all your cable assembly requirements, please contact us.

Wiring Solutions & Services

Wire Preparation – With our state-of-the art wire processing equipment we can process most types of wire. From solid core to multi-stranded wires with various insulation materials such as Silicon, PFTE/ Teflon or even fibre glass braided cable, we can do it all.

Battery Cables – We are able to cut and process battery cables up to 120mm². Our heavy-duty cutting equipment is designed to cut and strip the cable automatically. Cable lugs are fitted semi-automatically using heavy duty hydraulic crimpers to ensure crimp integrity.

Multicore Cables – The same equipment used to process the battery cable is used to cut and strip the outside sheath automatically of most multi core cables. The inner cores are stripped on a high precision semi- automatic bench top stripping machine and are then crimped or twisted and tinned as required.

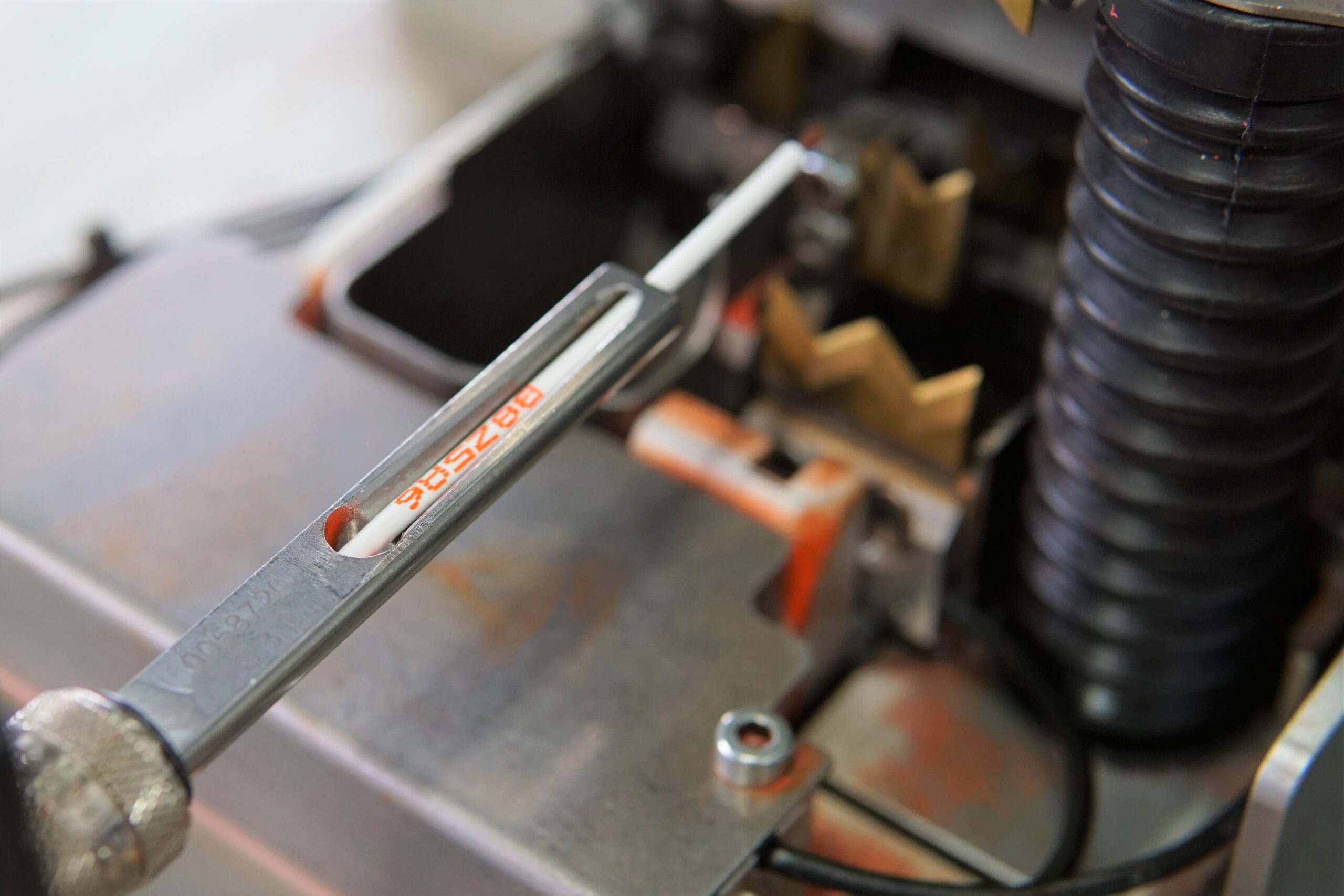

Wire Printing and Labelling Solutions – BJC understands how important it is to be able to quicky and accurately identify connections and components in an assembly, and as such we are equipped to provide you with many labelling options to suit your needs. From inkjet printing on wires to custom heat shrink labels, ask us about how we can make labelling work for you.

Process

Our Process: From Enquiry to Production Run and Beyond:

1. Initial Communication – You come to us with your requirements, drawings, or samples. No matter how in-depth or vague, we can work with you to figure out a custom solution for your application.

2. Design and Iteration – Our knowledgeable team consults you on the best course of action, putting forward ideas for improvements, alternate parts, and other design considerations based on our many years of experience in the industry.

3. Component Sourcing – BJC’s full time procurement staff work to find the components you need, no matter how niche. We work closely with many reputable suppliers to set up reliable supply lines, so your wiring solution gets to you when you need it.

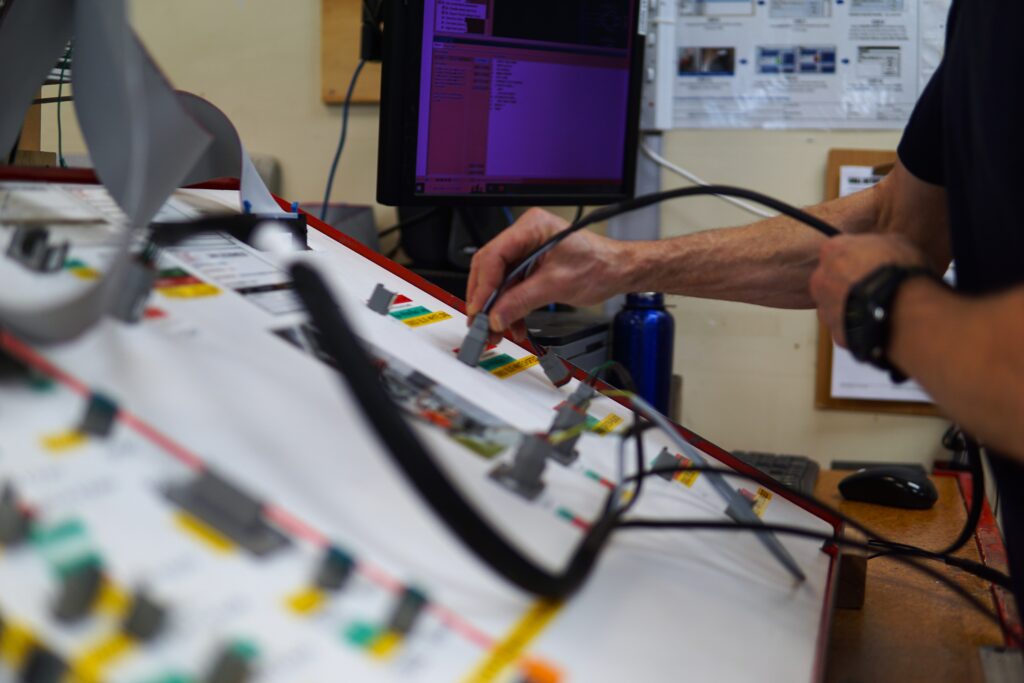

4. Prototype – To ensure that the design is fit for purpose and that the process is streamlined, we will often build a prototype of your wiring solution. Our Quality Control team will ensure that it meets all the required specifications, then it can be sent to you so you can provide feedback and do testing in situ. We will then communicate with you to make any changes you require.

5. Production Run – Our extensive manufacturing capabilities and capable team mean that we can build your wiring solution in a streamlined and flexible way. Being a NZ- based business, our lead times and minimum order quantities are much lower than overseas competitors and we will provide live communication should troubleshooting be required.

6. Testing – All of our wiring solutions are tested rigorously by our skilled Quality Control team using reputable automated cable testing equipment such as the Cami Research Cable Eye. We regularly build custom jigs and fixtures for specific testing requirements so you can ensure that you are receiving a wiring solution that will be of quality and will work first time.

7. Ongoing Communication – Custom manufacturing is an integral part of our business, and we pride ourselves on our communication – any revision changes or modifications you require on future production runs can quickly and accurately be put into production, and we will consult with you on any queries you may have.

Capabilities

Quality Control, Process Management, and Testing

Quality is at the heart of our operations, and we always endeavour to exceed our customers’ expectations in terms of our product quality and service levels. BJC has been in constant ISO certification since 1994 and currently hold ISO 9001 and AS/NZS 4801. Regular audits are conducted to ensure that the requirements of these standards are met, and we are fulfilling our commitment to continual improvement of quality and efficiency.

Testing: All product we manufacture is 100% electrically and visually tested using specialised testing equipment such as the Cami Research Cable Eye, and testing jigs that are manufactured custom for each loom and assembly. It is important to us to ensure that all product that leaves our factory is safe and meets all of our customer’s requirements. For specific or niche testing requirements, we have experience building and programming custom testing equipment.

Processing & QC: To ensure the tightest quality controls we adhere to strict quality protocols:

- Sample Process: FMEA, Control Plans, Capability Studies, and Customer specific Reports.

- Production Documentation: Work Instructions, Visual Aids, Flow Diagrams, SPC Charts, and Control Plans.

- Production: 1st off prototype batch, Customer approval/Sign off, In Process testing, Final testing, Ongoing Quality audits.

- Scheduling: Full Capacity and Tracking system for Customer orders through the factory to ensure we meet your delivery requirements.

- Training: Comprehensive fully documented training programme to ensure our people are kept up to date.

Manufacturing & Machinery Capabilities

BJC’s wiring division boasts a wide range of high-tech machinery and tooling, allowing us to process a vast range of wires, components, and materials. Much of our machinery is Automatic or Semi-automatic, ensuring process repeatability, quality, and cost-effectiveness.

Our in-house design and engineering team prides themselves on being able to manufacture with flexibility and process to very specific customer requirements. Where required, we can build jigs and offer custom solutions where conventional options are not sufficient.

- Komax Automatic Wire Processing Machines equipped with conductor detection and crimp force analysis.

- Komax Inkjet Printing: Custom printing can be automatically added to wiring as it is processed.

- Heat Shrink Label Printer

- Cosmic High Precision Wire Stripping Machine

- Macromelt Over Mould Machine: Over moulding & Low Volume, Low Temp Injection Moulding.

- Heavy duty benchtop cutters for processing battery cable and multi-core cables.

- Mecal Semi- Automatic Terminal Presses & an extensive range of Terminal Applicators

- Soldering Facilities

- Heavy duty electric crimpers & Hydraulic Lug Crimpers.

- 3D Printing Department

- Pull Force Testing Equipment

- Cami Research Cable Eye Automated Testing Equipment

- Ultrasonic splicing capabilities, and a variety of other splice options.

Source & Supply

When it comes to the supply and management of electronic /electrical components, mechanical components, and assemblies we can offer our extensive procurement and logistics experience. Along with the benefit of long-term relationships with both local and overseas supply partners, we are able to offer a diverse and cost-effective sourcing network. Part of the service that we offer is procuring niche components and offering suitable alternatives where required.

As part of our risk management programme, we monitor all suppliers on service, quality, flexibility, and price to ensure that they fit into our organisation. We conduct annual audits by onsite visits or through correspondence and share our results with them to help improve both organisations.

We are an ISO compliant facility and manufacture to all relevant standards. Our inventory and manufacturing processes comply with ROHS mandates.

Offshore Partnerships

Our strength lies in diversity, whether manufacturing onshore in our own manufacturing facilities and outsourcing, where required, or utilising one of our offshore partnerships who specialise in specific manufacturing processes.

So often, overseas organisations are geared up for high runs only. We have formed partnerships with organisations that can and will deliver on small orders with the same level of service as well. A lot of time has gone into selecting these partnerships, considering communication, level of expertise and trading history.